In 2019, the sheet-metal pressing, welding and cutting company Nitator-SLT diversified part of its production and began to orientate toward providing specialised services to industrial companies in Lithuania. Although 99% of the company’s production goes to Sweden, the company does not intend to remain focused just on the Swedish market. The company is actively searching for new growth opportunities. The 20% growth in Nitator-SLT’s profit is proof of that.

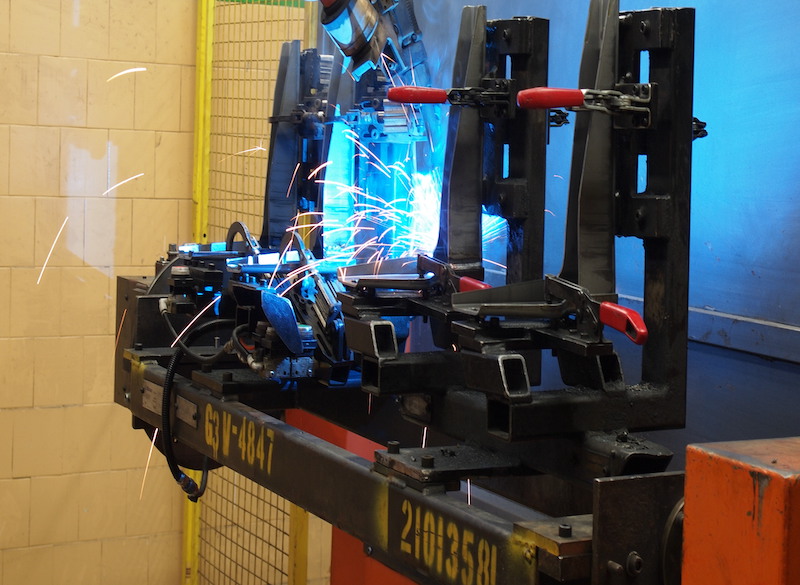

One of Nitator-SLT’s main activities is supply of sheet-metal components to clients with especially demanding requirements for quality, environmental responsibility and delivery precision. The company manufactures and supplies parts to clients including Scania, Volvo Trucks, Volvo CE, Volvo Cars, Renault and Nolato.

CEO Liutauras Variakojis explains that in 2019, it was especially important for the company to diversify its manufacturing capacity. In the last year, the focus was on the search for and realization in new areas of operation. He says that the company is open to actively cooperating with companies in the Baltic Automotive Components Cluster (BACC) as well as other companies operating in Lithuania. At present, specialised cutting (shearing) and welding works are performed at the factory for companies lacking such specialised equipment for order fulfilment.

As one excellent example of such cooperation, the CEO mentions Utena-based Elameta, which belongs to the BACC. Powder coating of parts produced by Nitator-SLT is performed at the company in Utena.

As one of the distinctive features of Nitator-SLT, Variakojis draws attention to the production of hose clamps, using specialised stainless steel with rounded edges. The hose clamps are made for Volvo and Renault trucks.

Asked if employees are hard to find, the CEO says that “the Biržai area was always an agricultural region, so there are plenty of qualified employees capable of working with welding, cutting (shearing) and other specialised equipment. Employees are loyal to the company, with some having worked at the company for 15 years. For its part, the company encourages all-round employee involvement in the company’s operations.”

In 2020, the company has set the goal of remaining profitable and focusing not only on the automotive industry, but also supplying even more specialised services to clients and achieving maximal productivity.

About the company’s headquarters in Sweden. Since 1983, Nitator has been a family-owned business. The company seeks not only to preserve its roots in responsibility and tradition, but also to make use of the most up-to-date production technology available. Nitator has grown rapidly since it began to focus on contract production for the automotive industry. In Lithuania, the Nitator-SLT unit was established in 2005. The quality of its products and services is especially important to the company, as it seeks to satisfy the needs of some of the most demanding clients in the world. Nitator management emphasises the responsible attitude of employees to the highest standard of quality throughout the production process, the purpose of which is to avoid even the smallest of manufacturing defects.