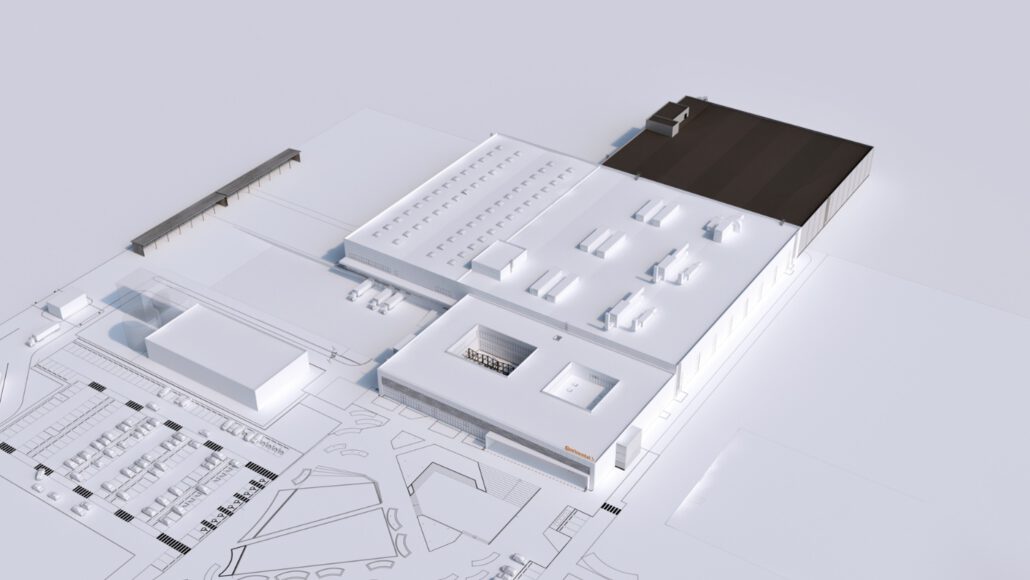

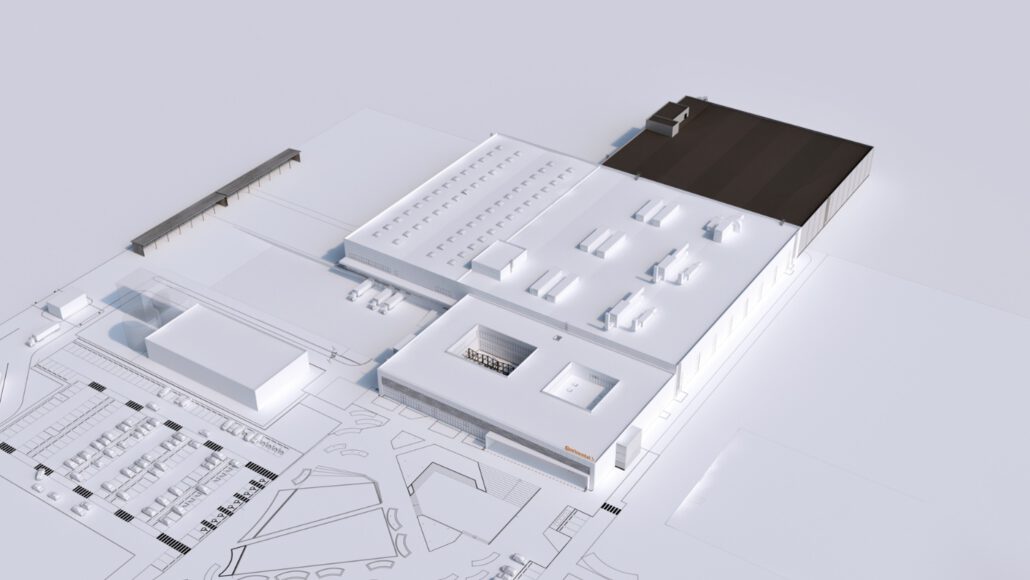

Continental Lithuania has completed in less than a year the first stage of its project to develop its electronics factory in Kaunas. The production zone was expanded by 5,000 square metres, and additional office space amounting to 1,600 square metres was built. The newly-expanded production zone will operate at full capacity in 2023. In the second stage of development, facilities for production, office space and warehousing will be expanded.

The portfolio of products manufactured at the Kaunas factory will remain the same; the focus will remain on automotive parts for safety, comfort and autonomous steering functions. The electronic components manufactured in Kaunas can be found in the latest car models.

It is planned to begin the second stage of development at the beginning of 2023. When the second stage is completed, the office and warehouse facilities will expand by 3,000 and 2,500 square metres, respectively. The production area will also expand by more than 5,000 square metres. The Continental factory in Kaunas will expand by a total of more than 17,000 square metres.

After the last stage of development, the company’s production capacity in Kaunas will more than double. Total investment in the Kaunas factory will amount to more than 190 million euro.

The Continental Automotive Lithuania factory building has been designed and built in accordance with the LEED Gold international sustainable building standard, which requires exceptional attention to building processes, the environment and sustainability. The building design received the Lithuanian BIM Projects 2022 prize in the manufacturing-building category.

The factory’s operating parameters and energy management system control are automated, with smart environment-friendly engineering solutions. The systems ensure effective climate control and efficient use of energy. Smart interior lighting solutions are used in the buildings; lighting intensity is regulated and managed remotely, selecting the optimal lighting for employees. A healthy microclimate is maintained inside the facility, with precise control of temperature, humidity and dust levels.

UAB Continental Automotive Lithuania was registered in Lithuania in October 2017. The factory, located at the Kaunas FEZ, began manufacturing operations in autumn 2019. At present, almost 700 employees work at the company, and it is planned to have a team of 1,500 by 2025.

14 separate electronic components are produced at the facility in Kaunas, including control units for car doors and seats as well as electrochromic glass control units to reduce light passing through car windows automatically or according to user settings.